Easy to operate Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Easy to operate Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

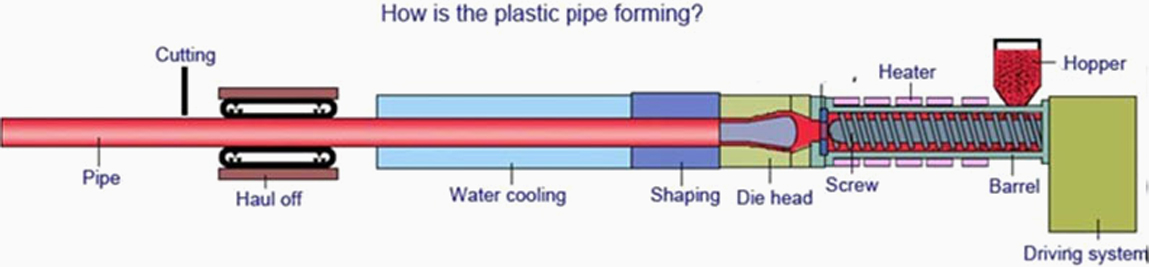

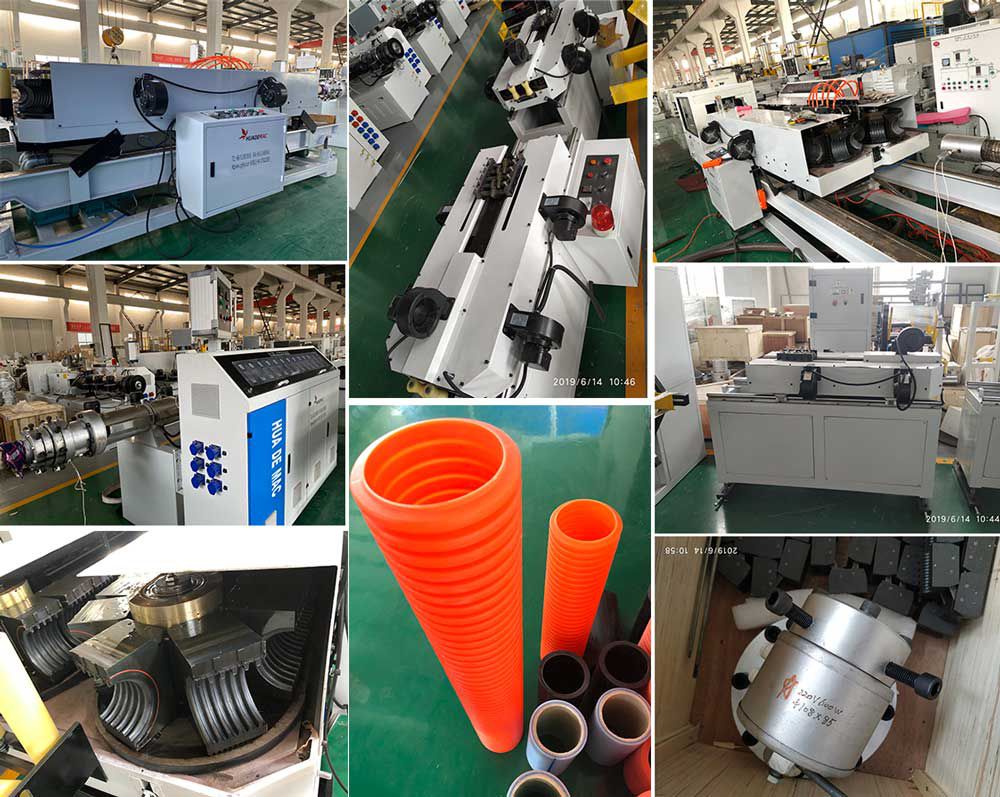

PP, PE, PVC Single Wall Corrugated Pipe Production Line mainly produces a single-wall corrugated pipe.

The professional screw and mold design reduces wear on the screw and barrel and makes the tube and easy to shape.

The pipe is widely used in wire and cable threading pipe, car or train internal line protection pipe, washing machine to drain, agricultural irrigation and other fields.

The Single Screw Extruder

Driven motor: It is main part of single screw extruder. We'd better choose good brand AC type driven motor matching with inverter controll for saving power running cost.

Gear recuder box: It is used for connecting motor and for reducing rotating speed of screw through size and teeth of gear changing in the gear box.

Screw and barrel: It is most important part of single screw extruder. Design of single screw is becoming to special and customzied now due to many different kind plasic materials are using. The surface of screw should be paint double alloy for anti-wear.

Casting aluminum heater: It is used for heating barrel and screw which ensure mixed PVC/PE/PP resin material can be plasticizing and melting under the suitable temperature.

Cooling blower : It is used for cooling barrel and screw. if temperature of screw and barrel will be excess setting temperature,cooling blowers start to work for cooling barrel which avoid PVC/PE/PP material resolved in the inside of barrel.

Hopper : It is used for keep the mixed PVC/PE/PP resin material in the silo and make sure material can be into barrelcontinuously. It is like a material transport station.

Control Cabinet: It is used for control whole cornic double screw extruder running by switchs or PLC programes according to different circuits control required.

Model | Die Block (pcs) | Pipe Range (mm) | Line Speed (m/min) | Output (Kg/H) |

XS-25 | 44 | 8-25 | 4-10 | 8 |

XS-32 | 44 | 16-32 | 2-7 | 30 |

XS-63 | 44 | 20-63 | 1-6 | 60 |

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !