Introduction to the delivery process

The Vietnam customer choose 3 suppliers for comparison before last decision, he came and check our machinery before he placed the order.

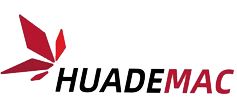

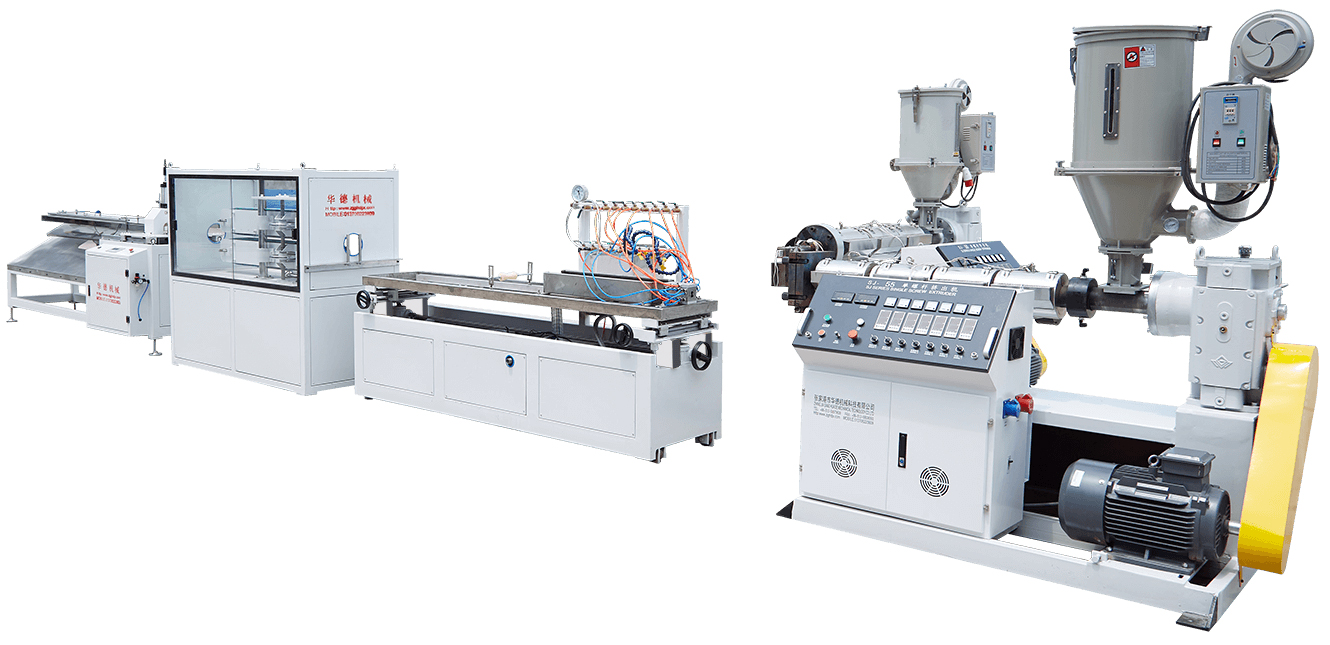

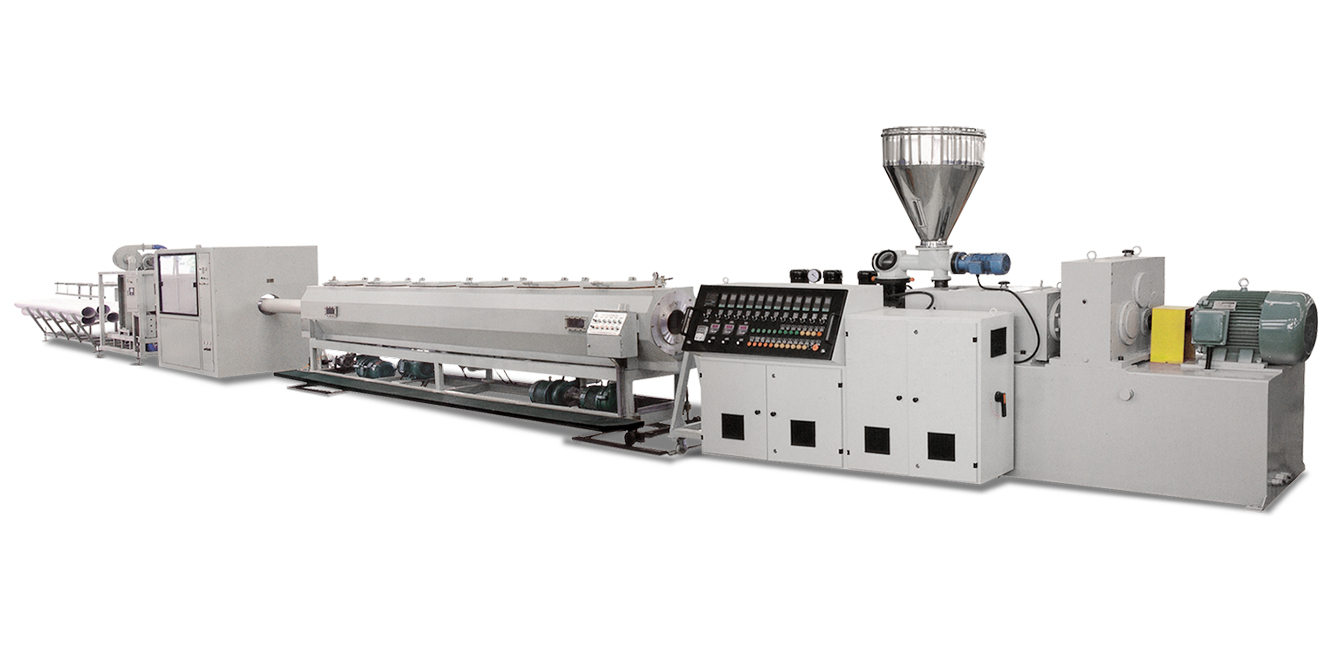

He already have 3 plastic pipe extrusion line in factory,2 PPR pipe (20-63mm ) and 1 HDPE pipe (75-250mm ),he want to set up 2 PVC pipe production lines? this time after he get the market research from local, one line for electrical conduit use diameter range 16-40mm ,the other line for water convey as drainage use diameter range 50-160mm,we recommend him our 2 strand extrusion line for small diameter and single extrusion line for big diameter, he was pleased? with our recommendation and signed the sales contract on 10th? March, we get the down pay on 15th March after he return back.

He came and visit factory again on 18th April, his purpose of this trip is to see the machines running before shipment, our engineer arrange everything before his coming such as wiring connect, water and compressed air supply, after 2 hours preheating, the pipe came out successfully at one time, he was very satisfied with our machine quality and quality of finished pipe, we loaded all machines into 2X40GP container on 25th April, our customer indicate us he will purchase another PVC pipe production line next year.