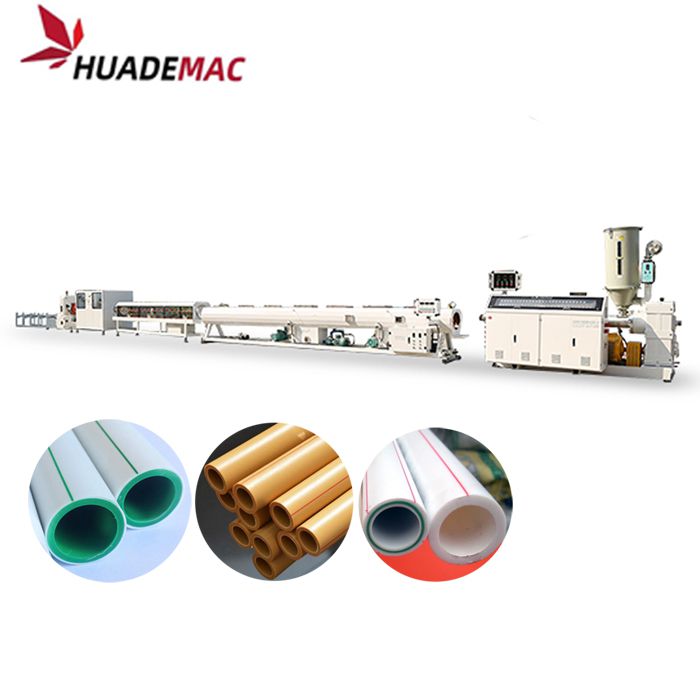

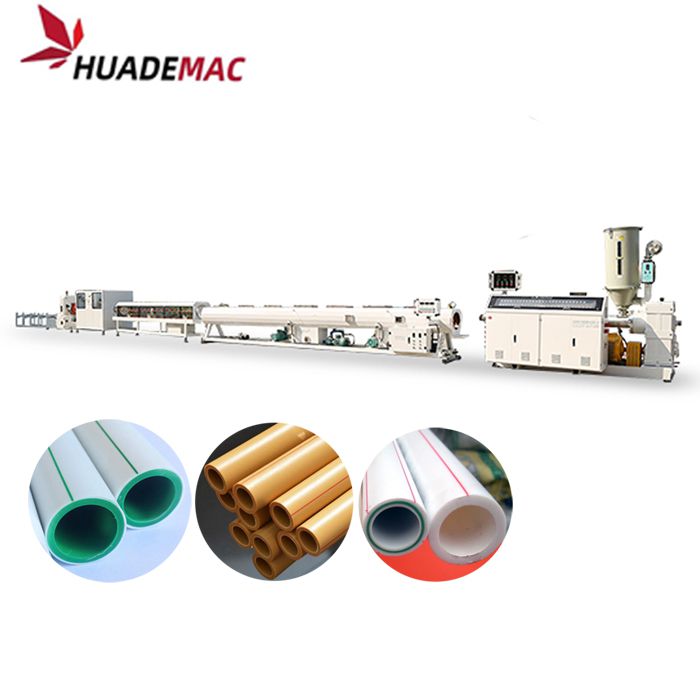

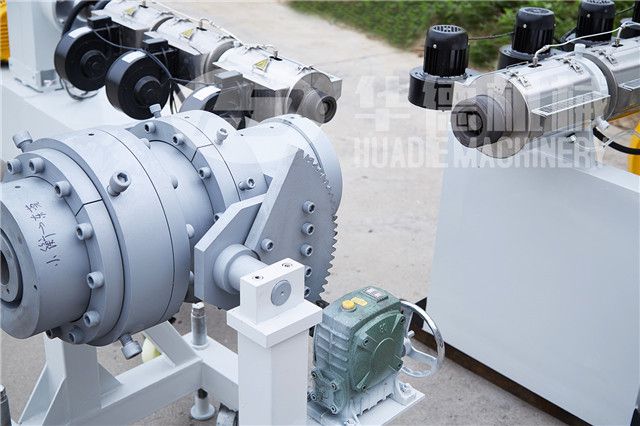

The complete extrusion line to manufacture the PPR hot and cold water pipe diameter from 20-160mm.

- Any Questions?[email protected]

- Get in Tough+86-13601562675

The complete extrusion line to manufacture the PPR hot and cold water pipe diameter from 20-160mm.

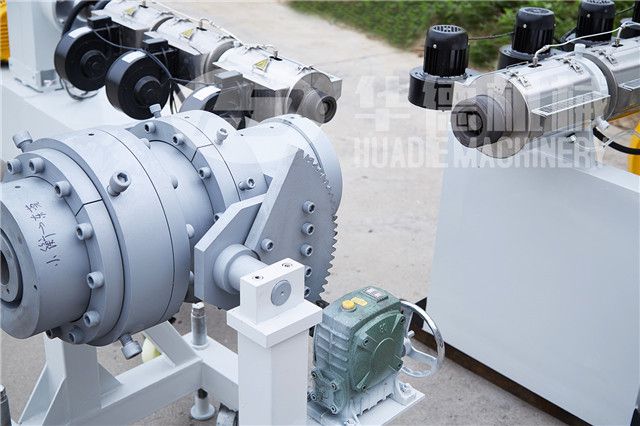

Extruder with special barrel feeding structure can largely improve extrusion capacity.

Accurate temperature control, good plasticization, stable operation.

The complete line adopts PID or PLC control system, realizing synchronization and automation.

Spiral and lattice basket type die head for choice.

Dust-free knife cutter and saw cutter for choice.

Changing some parts of the line can also realize two-layer and multi-layer co-extrusion.

Pipe Diameter | 16-63mm | 20-110mm | 50-160mm |

Max Output | 120kg/h | 180kg/h | 300kg/h |

Production Rate | 5-15m/min | 2-12m/min | 2-10m/min |

Extruder Model | SJ-65/33 | SJ-65/33 | SJ-75/33 |

Installed Power | 80kw | 140kw | 180kw |

Center Height | 1000mm | 1000mm | 1000mm |

Installation Area | 35*3.0*2.0m | 38*3.1*2.2m | 38*3.2*2.2m |

1. The civil-use and industrial-use construction inner cold/warm water and water-giving systems;

2. Public sites, (such as schools, hospitals), gyms(such as swimming pools, playground);

3. Drinking water systems and food industry management system'

4. Garden and warm rooms irrigating systems;

5. Traditional heat-giving/ heat-absorbing systems;

6. Central air-conditioner system;

7. Chemical flowing transferring pipe system.

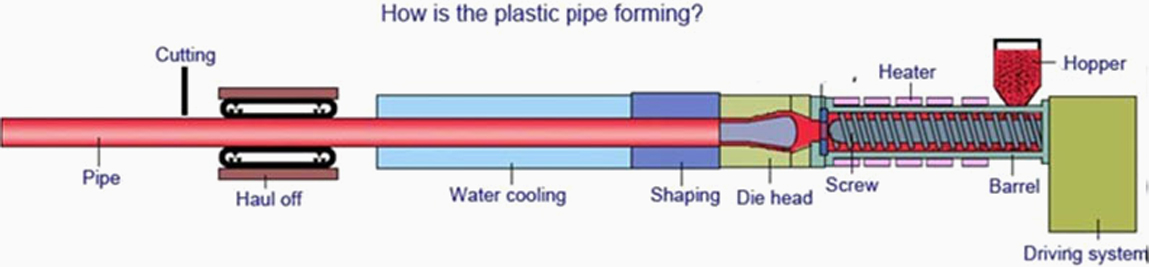

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !