Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

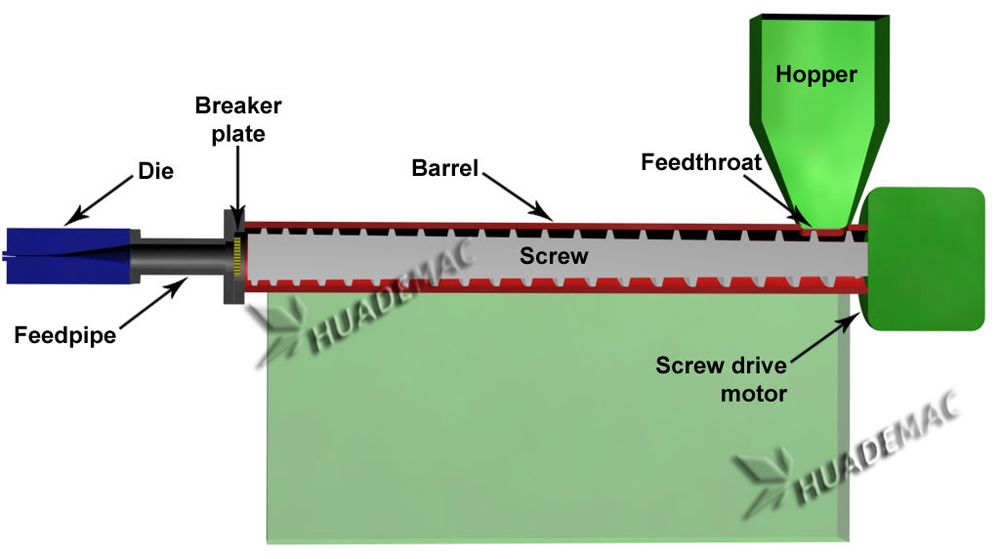

It can process all kind of plastics products with auxiliary machines concerned, such as film, pipe, stick, plate, thread ,ribbon, insulating layer of cable, hollow products and so on .It is also used in graining. The machine design is advanced, production capacity is high, plasticization is good, and energy consumption is low. The extruder adopts hard gear surface for transmission. It has advantages of low noise, smooth operation, large loading, long use-life and so on.

Suitable screws: 25,30,45, 65, 75,90, 120, 150,

Controller: Normal, PID or PLC (optional)

Can be combined with various auxiliary machinery

Length / diameter ratio can be changed (suitable between 25: 1 - 38: 1)

Specially designed screw, high-torque decelerator and high power DC motor ensure good mixture of material and high output

More flexible processing range; it can be used for recycling, pelletizing, pipe, profile, board/sheet/film extrusion.

Advantages:

Lower specific energy consumption; energy saving could be up to 30% plus.

Higher capacity: the capacity could be 50% more at the same diameter

Higher efficiency in plastication.

Better mixing effect: it is comparable with normal twin screw extruder

More accuracy in extrusion processing control.

Model | Screw diameter (mm) | L/D ratio | Main motor power (KW) | Capacity (kg/h) |

SJ-25 | 45 | 25/1 | 2.2 | 5 |

SJ-30 | 30 | 25/1 | 5.5 | 10 |

SJ-45 | 45 | 25-33/1 | 7.3-37 | 50-150 |

SJ-65 | 65 | 25-33/1 | 22-90 | 60-250 |

SJ-75 | 75 | 25-33/1 | 55-110 | 200-350 |

SJ-90 | 90 | 25-33/1 | 37-185 | 180-550 |

SJ-120 | 120 | 25-33/1 | 75-280 | 320-800 |

SJ-150 | 150 | 25-33/1 | 90-355 | 400-1200 |

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !