PE PP Recycling Pelletizing Line PP PE Waste Film Woven Bag Pelletizer PE PP Compactor Type Pelletizing Machine PE Film Granulating Line

- Any Questions?[email protected]

- Get in Tough+86-13601562675

PE PP Recycling Pelletizing Line PP PE Waste Film Woven Bag Pelletizer PE PP Compactor Type Pelletizing Machine PE Film Granulating Line

Belt Conveyor

As standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls’ scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor’s room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding.

Compactor / Agglomerator

The rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

Extruder

A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 36D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with water content

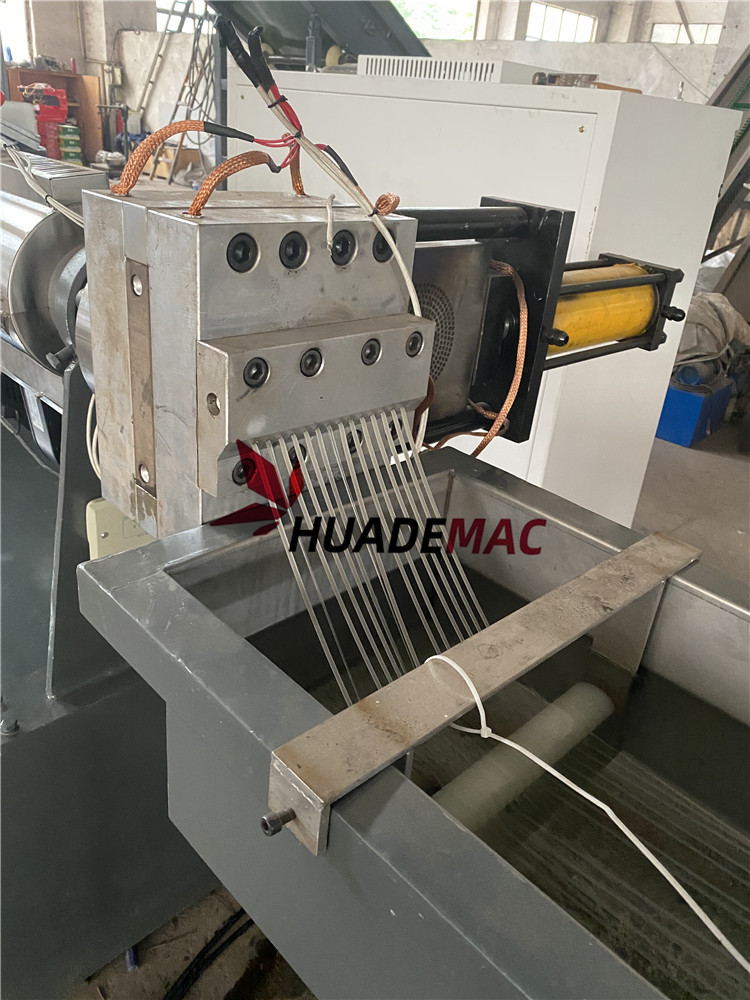

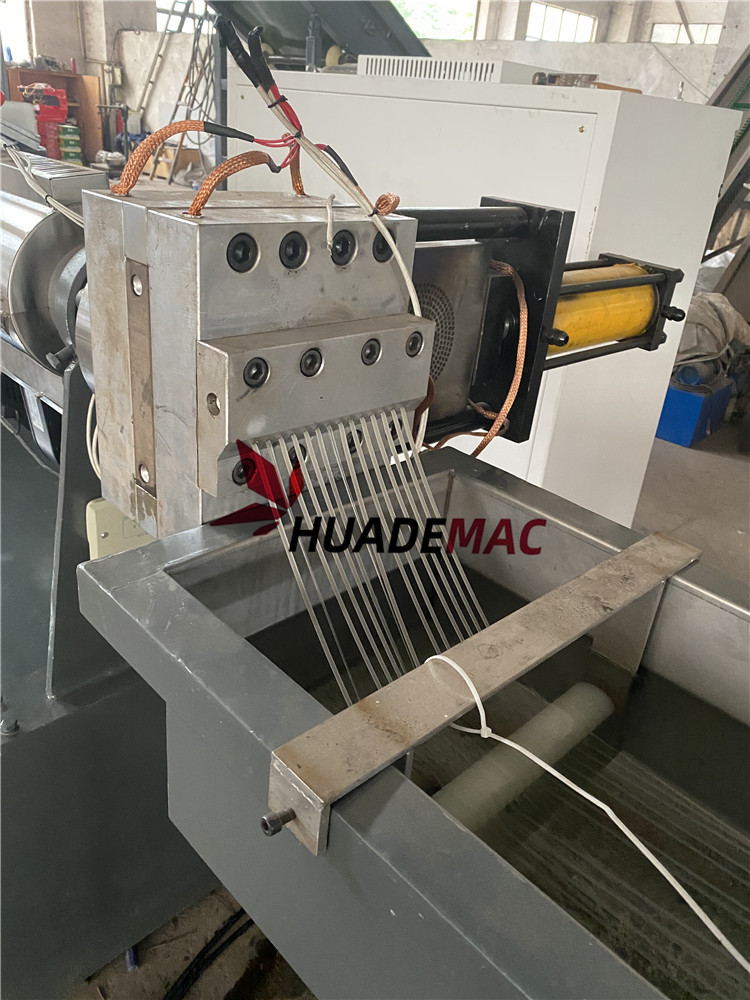

Noodle Cutter Strand Type Cutting System

The length of the sink is 4 meters, which can be adjusted up and down, and the stainless steel pipe is designed to change water.

The sink is made of 2mm thick stainless steel plate.

Vibration drying system

Advanced dewatering vibration sieve combing with horizontal-type centrifugal dewatering present high performance dried pellets and lower energy consumption.Combine crushing, compacting and plletizing steps in one system, less-labor cost.Higher efficiency feeding, suitable to film, filament, raffia, foaming materials;Higher output and lower energy consumption

Extruder model | Compactor Power(kw) | Extruder Power(kw) | Capacity(kg/hr) |

SJ85 | 37 | 55 | 180-250 |

SJ100 | 55 | 90 | 250-300 |

SJ120 | 75 | 110 | 300-400 |

SJ130 | 90 | 132 | 400-500 |

SJ150 | 90 | 160 | 500-600 |

SJ160 | 110 | 185 | 600-700 |

SJ180 | 160 | 250 | 800-1000 |

Applicable plastic materials: PE, HDPE, LDPE, LLDPE, etc

Material shapes: film, bag, non woven fabric, (PE, PP) regrind

Material types: (rolls, loose, bundled),

Material comes from offcut, industry defective film and washed film