Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

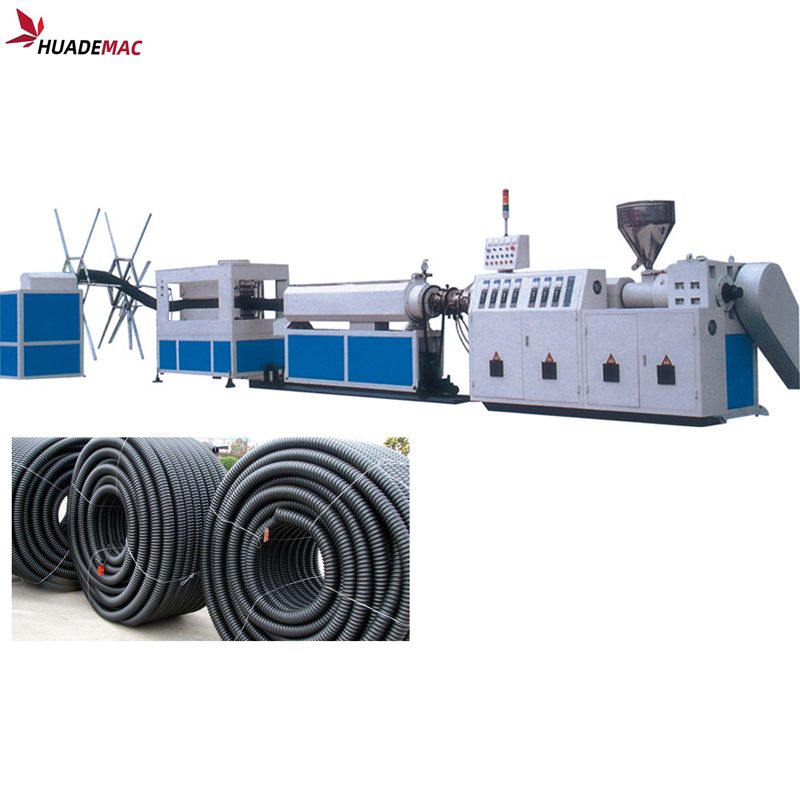

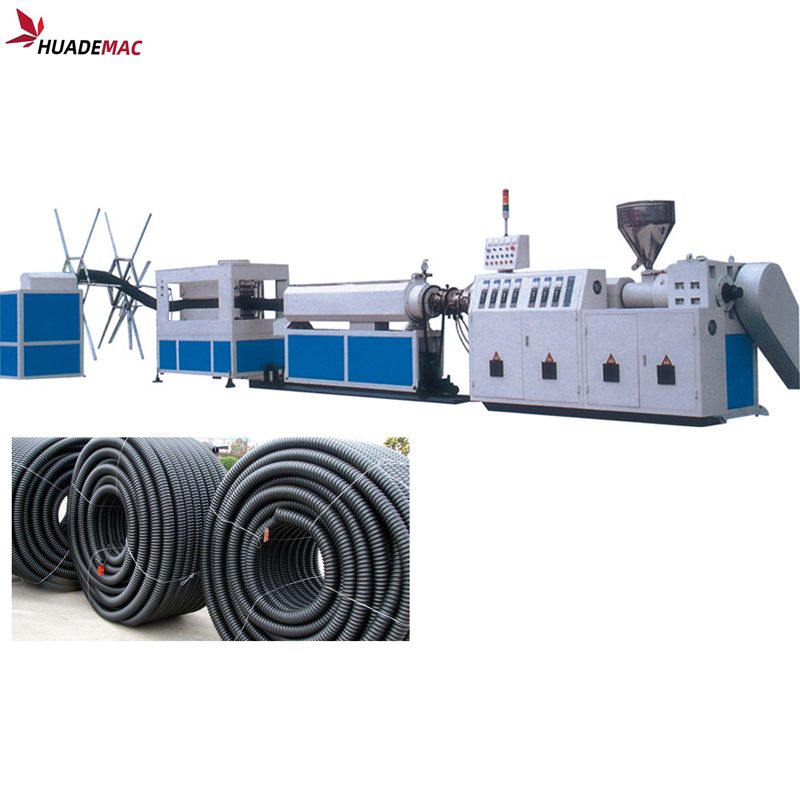

This PE Carbon Reinforced Spiral Pipe Extruder Machine is mainly used to produce PE spiral pipes which are largely used as protecting sleeves of optic or electric cable, and they are increasingly used in fields of electricity, telecom, post activities, constructions of express way, port, etc.

These pipes are characterized by high intensity and tenancy, erosion resistance, constant shape and easy transportation and execution, etc.

They can be processed and bent into long pipes with various radians. Owing to these advantages, they are very popular with clients engaged in many fields.

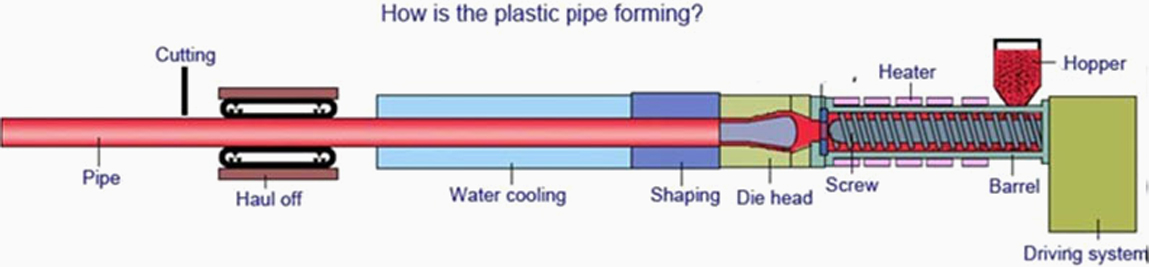

Dedicated single-screw extruder is especially used for producing polyolefin products, and the specialized separating type mix-melting screw possesses features of high-speed extrusion and plasticization, etc.

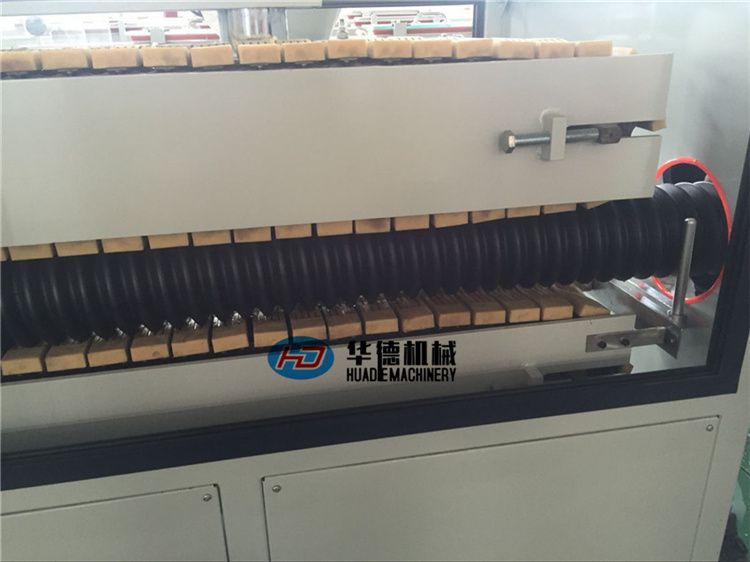

The pipe die head is designed in standard, and the reasonable flowing path ensures smoothness of the inside and outside walls of the pipe. The way of assembling the die head is designed according to the client's requirement, which saves much room.

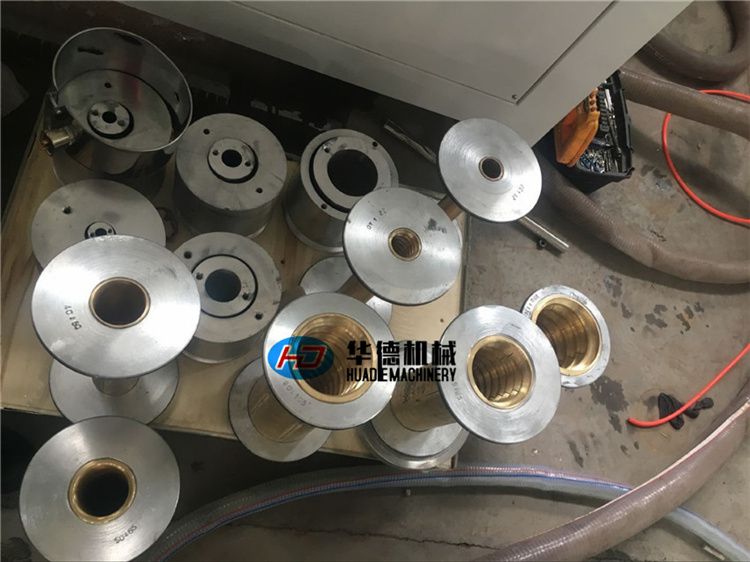

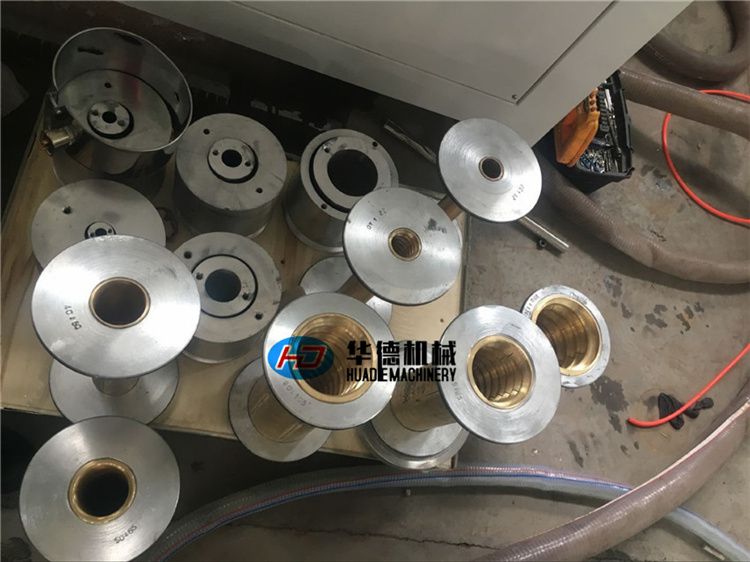

Both scientifically designed copper spiral sizing sheath and the powerful inhaling vacuum device contribute to high extrusion of the pipes.

The tank is made of stainless steel, and automatic controller is used to control the liquid level. The peculiar spraying nozzle brings about effective cooling and the motor ensures longitudinal movement and three-dimensional adjustment in terms of the directions of upward, downward, left and right.

Extruder | SJ-90/30B single extrusion | SJ-65/30B single extrusion | SJ-75/30A two strand extrusion |

Die | φ75-φ200 | Φ30-φ100 | Φ30-φ100A |

Calibration Water Trough | CTWL-200 | CWTL-100 | CWTL-100A |

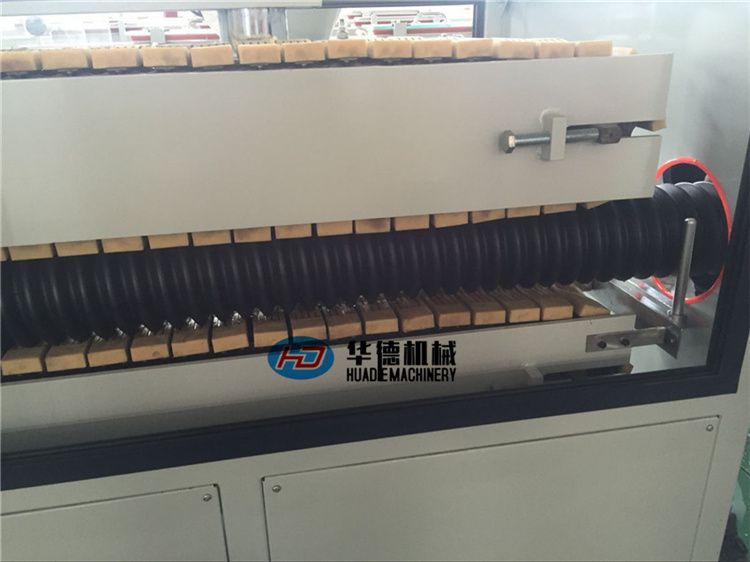

Hauling | HM-200 | HM-100 | HM-100A |

Winder | WG-200 | WG-100 | WG-100A |

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !