Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

SJSZ series conical twin-screw extruder has advantages such as forced extruding, high quality, wide adaptability, long working life, low shearing speed, hard decomposition, good compounding& plasticization effect, and direct shaping of powder material and etc.

This extruder is suitable for matching with production line of plastic pipe, plate and profile and etc

This series of extruders are applied to PVC pipe extrusion line, PVC profile extrusion line, PVC modification pelletizing line, wood plastic composite product extrusion line.

Features:

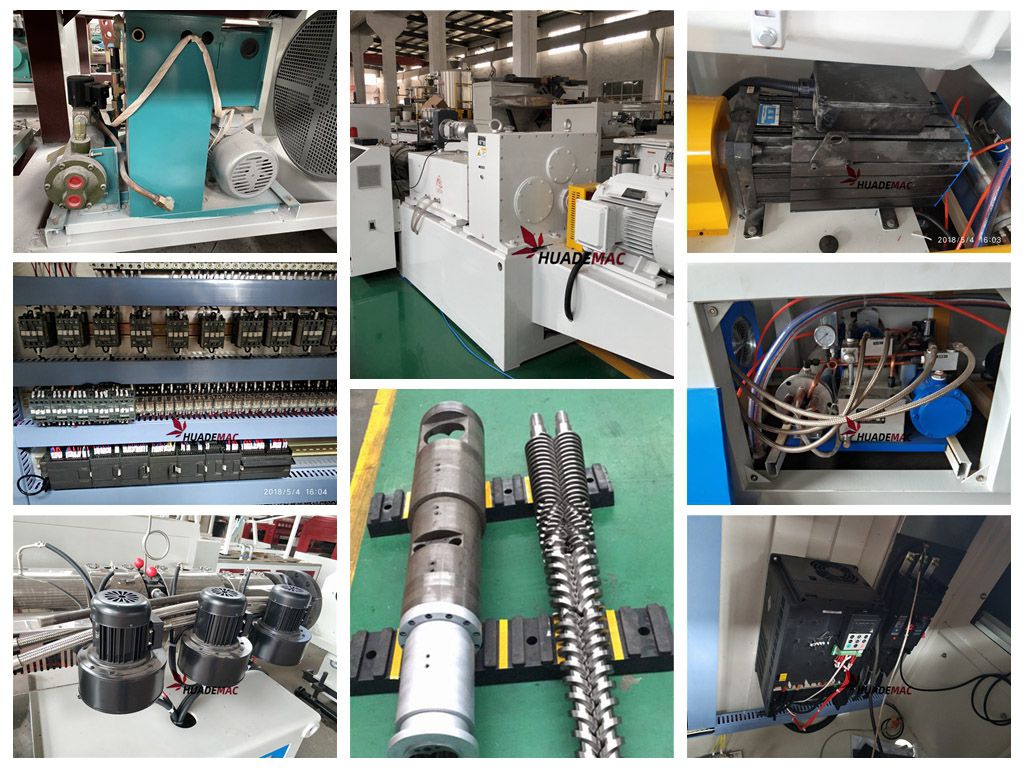

Nice looking,, compact structure, space-saving;

World class DC/AC control system and sectional malfunction alarming make measuring and maintenance easily;

High-performance reducing torque-distribution system guarantees reliable and quiet running;

Flexible air cooling/oil cooling system reduces running cost;

Optimized designed, carefully fabricated screw shafts and barrel bring an extremely good plasticization;

Under the prerequisite of keep a high melt quality, it realizes a maximum extruding ability.

Model | SJSZ45 | SJSZ51 | SJSZ55 | SJSZ65 | SJSZ80 | SJSZ92 |

Screw Diameter (mm) | 45/90 | 51/105 | 55/110 | 65/132 | 80/156 | 92/185 |

Speed Of Screw (R/Min) | 1-45.5 | 1-42 | 1-40 | 1-38 | 1-36.9 | 1-34.7 |

Effective Screw Length (mm) | 989 | 1070 | 1200 | 1440 | 1800 | 2500 |

Main Motor Power\ (Kw) | 15 | 18.5 | 22/30 | 37 | 55 | 110 |

Barrel Heating Power(Kw) | 11.5 | 16 | 18 | 24 | 36 | 86 |

Capacity (Kg/H) | 80-100 | 100-120 | 150-180 | 250-300 | 320-400 | 600-800 |

Central Height (mm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

Net Weight (Kg) | 2800 | 3000 | 3500 | 4000 | 5000 | 6000 |

Appearance Size LXWXH (mm) | 3300x1200x2127 | 3300x1400x2130 | 3620x1350x2157 | 4235x1520x2450 | 4750x1550x2460 | 6500x1600x2500 |

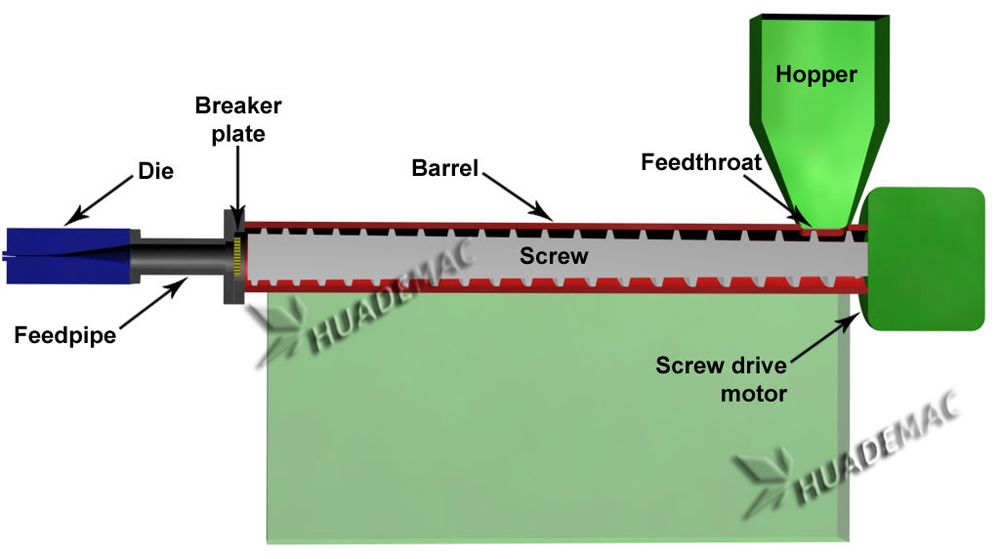

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !