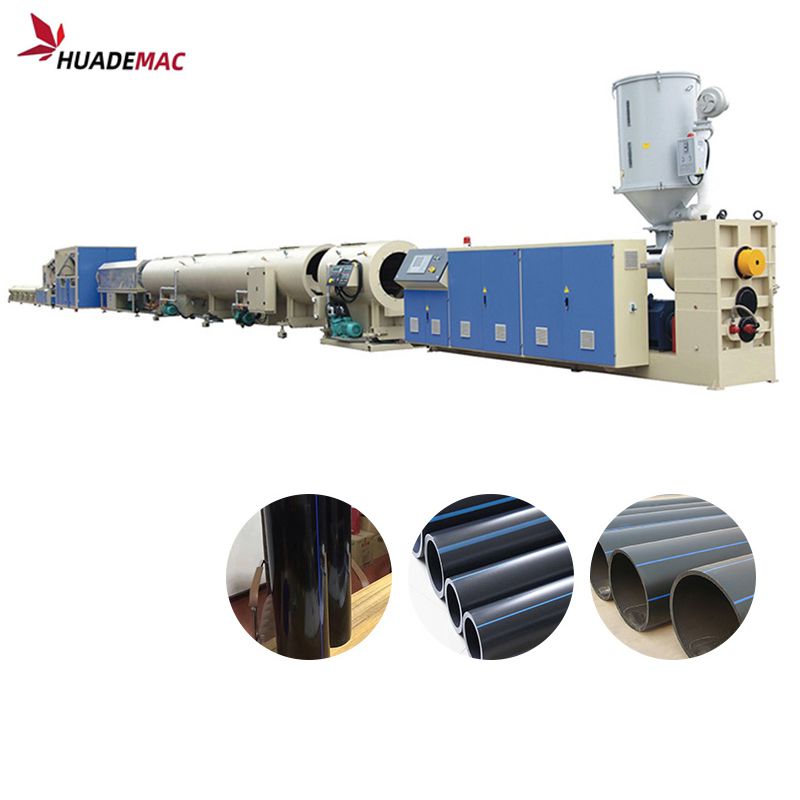

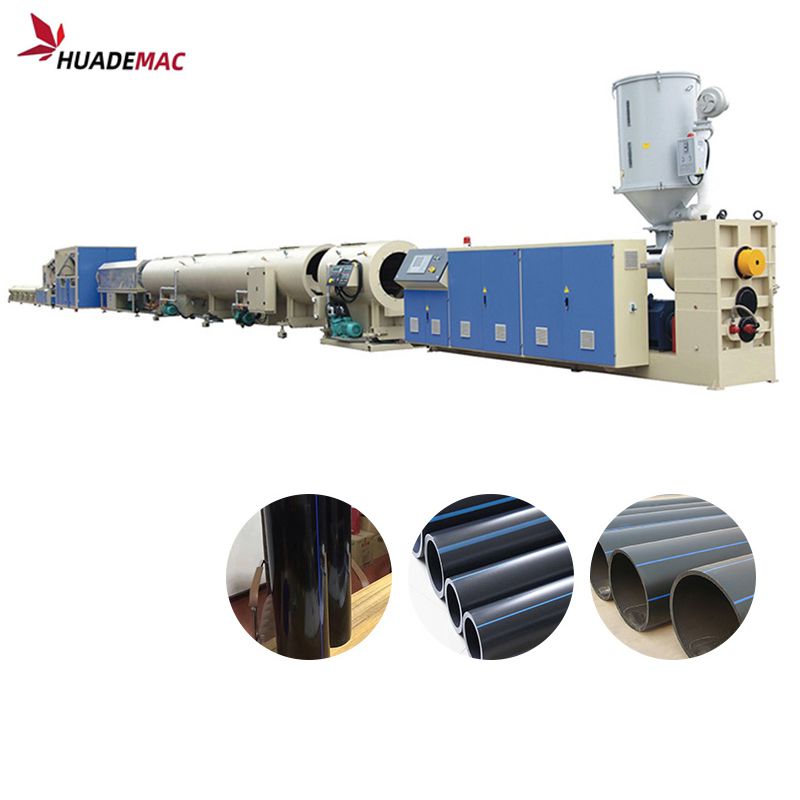

Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

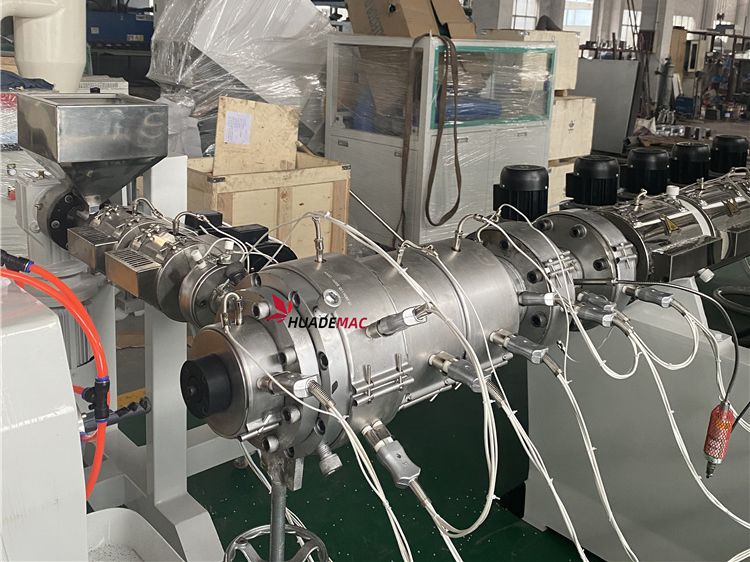

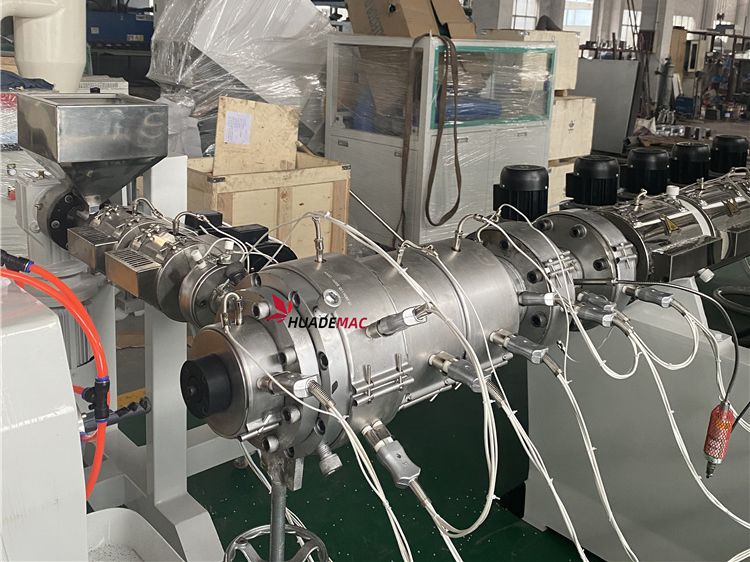

The extrusion line employ high capacity single screw extruder to ensure stable and high output .

Compact design takes up less room and enables a flexible layout of the assembly line.

Competent for producing pipe with diameters range from 16mm to1600mm.

Customer-oriented design can meet specific requirement of different customers.

All-around technical and comprehensive supports before and after sale services ensure a smooth and care-free operation of this line.

A number of adoptions of automation can precisely control the process thus resulting in a solid quality of final product.

Pipe Range (mm) | 16-63 | 20-110 | 75-250 | 110-315 | 160-450 | 315-630 | 400-800 | 710-1200 |

Extruder Model | 65/33 | 65/33 | 65/33 60/38 | 90/33 65/38 | 120/33 75/38 | 120/33 90/38 | 150/33 | 120/33 90/33 |

Extruder Motor (Kw) | 37 | 55 | 110 | 132 | 160 | 280 | 355 | 280 160 |

Max.Capacity(Kg/h) | 120 | 180 | 330 | 380 | 450 | 750 | 900 | 1200 |

The civil-use and industrial-use construction inner cold/warm water and water-giving systems;

Public sites, (such as schools, hospitals), gyms(such as swimming pools, playground);

Drinking water systems and food industry management system'

Garden and warm rooms irrigating systems;

Chemical flowing transferring pipe system.

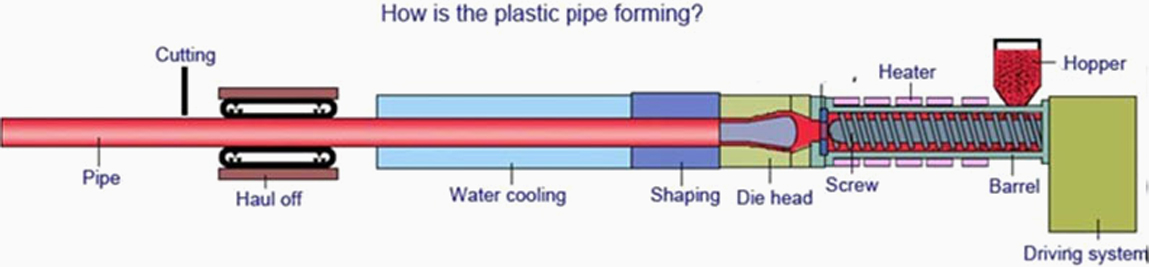

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !