Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Do you know how plastic pipes are manufactured? Let's get started!

Generally, plastic is considered an organic polymeric material (composed of giant organic molecules) that can be deformed to a desired shape by extrusion, molding or spinning. The molecules can be of natural origin, for example cellulose, wax or synthetic rubber such as polyethylene and nylon.

The PVC occupies a privileged position in the plastics family because of its interesting set of properties, as it is a light, resistant, inert and completely harmless material, good fire behavior (it does not spread with flame, it is self-extinguishing), waterproof, insulating (thermal, electric and acoustic), weatherproof, high transparency, has a good quality / price ratio, is easy to transform (extrusion. Injection, calendering, thermoforming, pressing, coating and pasta molding), and is fully recyclable. The PVC pipe machinery plays a huge role in these processes.

Let's look at the processes adopted in the manufacture of plastic pipes

The steps through which PVC resin passes to become pipes are basically reduced to extrusion, processing, welding and assembly, placement of joints, and glazing. The way in which each of the processes is carried out is designed with the objective that PVC pipes offer their peculiar advantages to the consumer.

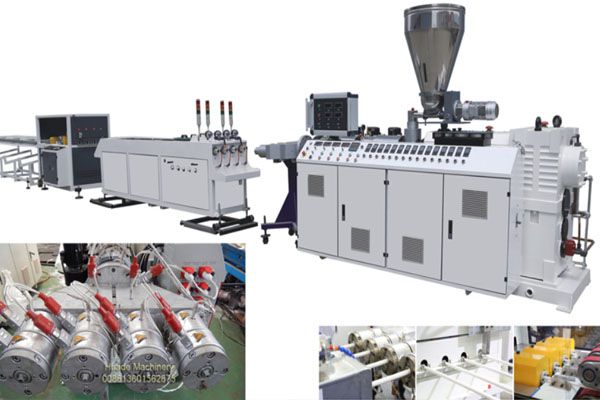

EXTRUSION: Extrusion is the method of thermoplastic transformation that gives shape to the molten raw material. This shape is limited to two dimensions, that is, it develops in the plane perpendicular to the axis of the movement of the material.

From the PVC raw material, window profiles are manufactured in extruders using the pipe extrusion machinery. The process consists of introducing PVC powder or grain along with its additives at one end of the machine. At this time, they go through a melting process. At the other end of the extruder, the profile comes out through a nozzle with the shape it will take. The next step is to cut the PVC bars in lengths of five to six meters.

ELABORATION: After cutting the PVC bars, the reinforcement profiles are placed according to the dimensions and specifications of the profile manufacturer. Then the T-shaped or cross-shaped joints are made by welding the PVC profiles or mechanical joint (screwed).

PLACEMENT OF JOINTS: Between the leaf profiles, the frame and post, synthetic rubber gaskets are placed, which are necessary to avoid the appearance of air currents, guarantee greater technical and acoustic insulation.

GLASSING: When placing them, the joints with drainage and aeration openings are used to deflect the penetration of water that causes fogging.

PVC pipe extrusion machine prices vary in the global market. However, this is dependent on factors such as the model, the size and other company features. It is important to liaise with reputable manufacturers of pride you with top quality equipment for your industrial PVC pipe manufacturing needs.

HD extrusion is a Professional plastic pipe extrusion machine manufacturer dedicated in the supply of excellent quality machinery to meet to increasing global demand for PVC pipes. You can learn more here.