Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

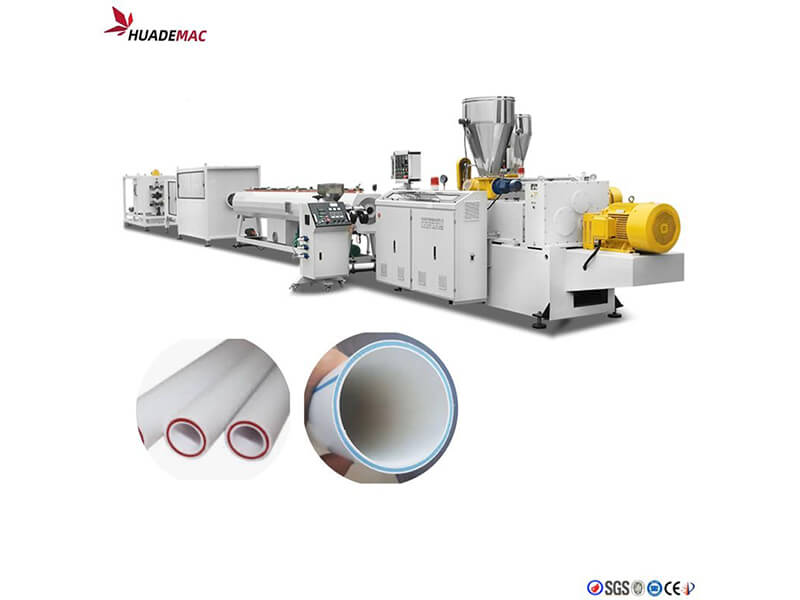

In recent years, China's plastic pipe extruders have developed rapidly, the annual growth rate of PVC pipes has reached 8%, and the annual growth rate of demand has reached 2%. Among plastic pipes, the consumption of PVC pipes is far ahead, and it is widely used in water supply and drainage pipes. Due to the relatively mature technology, in recent years, PVC water supply pipes have not invested much in product innovation, relatively few new products, more common products on the market, less high-tech and high value-added products, and most of the same general products and low-end products. There are fewer high-end products.

In the production process, since the PVC pipe is a heat-sensitive material, even if a heat stabilizer is added, it can only increase the decomposition temperature and prolong the stabilization time without decomposition, which requires strict control of the molding temperature of the PVC pipe. Therefore, the extrusion temperature should be determined according to the formula, extruder characteristics, mold structure, screw speed, temperature measurement point position, thermometer error, temperature measurement point depth and other factors.

PVC pipe production line directly affects the pipe output and pipe wall thickness. The instability of the traction speed will lead to the increase or decrease of the PVC pipe diameter. The pulling speed should closely match the tube extrusion rate. In normal production, the pulling speed should be 1% or 10% faster than the extrusion speed. The slower the traction speed, the thicker the pipe wall, the faster the traction speed and the thinner the pipe wall, which will also increase the longitudinal shrinkage and internal stress of the PVC pipe, thereby affecting the pipe size, qualification rate and use effect. The following simple methods can be used to adjust the pull rate in production. The extruded PVC pipe is placed in the traction track, but the track does not clamp the pipe. A difference was observed between the linear velocity of the track and that of the PVC pipe. If the pulling speed is slower than the extrusion speed, adjustments should be made until the wall thickness is satisfactory.

machine is equipped with a quantitative feeding device to match the extrusion volume with the feeding volume to ensure stable product extrusion. Due to the characteristics of the conical screw, the diameter of the feeding section is large, the heat transfer area and shear rate of the material are large, which is conducive to the plasticization of the material, and the diameter of the screw in the metering section is small, which reduces the heat transfer area and shear rate of the melt. cutting speed. Thus the melt can be extruded at lower temperatures. When the screw rotates in the barrel, the PVC mixture is plasticized and pushed to the machine head to achieve compaction, melting, mixing and homogenization, and achieve the purpose of exhausting and dehydrating. The feeding device and screw driving device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.