Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

What Is The HDPE Pipe?

HDPE pipe, Polyethylene (PE pipe) is arranged on their strength and grouped based on the intensity of the former technological developments.

The HDPE pipe pressure groups which are possible for productions are between Pn4-Pn32.

Also, the HDPE pipe pressure pipe system has passed through several tests in 1950 with the production of preferred diameter and size, specifically, during the carriage of heavy water.

After the tests of the HDPE pipe, if the results show in the report they are all positive, that means; it is not harmful to human life.

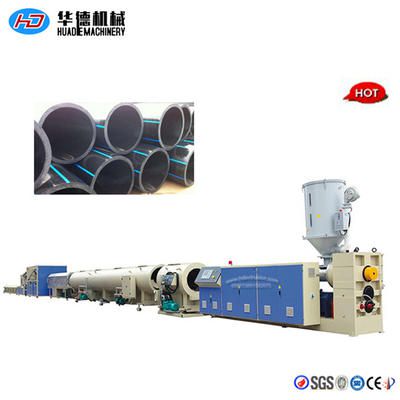

The HDPE pipe is one of the most generally used pipe which is easy to handle, with efficient performance, easy to couple and economical and they are produced by HDPE pipe extrusion line.

However, if you are interested in getting an HDPE pipe extrusion line, it is best to contact a professional HDPE pipe extrusion line suppliers for the best HDPE pipe extrusion line price and product.

Raw Material Of Polyethylene Pipe

When Polyethylene Pipe, PE 32, the class was invented in 1950 with improved low density and technology.

Third generation PE 100 polyethylene raw materials are mostly used in sea discharge lines, gravity flow water lines, gas stations, biological treatment plants, swimming pool piping, drinking water pipelines, desalination plants,

The PE 100 polyethylene raw materials are also used in irrigation lines, compressed air lines, cooling-heating lines, pre-insulated sheathing for pipes.

Because low-density polyethylene pipe has high performance and it is economical in various areas.

The C2H4 contains the usual formula of crude oil, which is about 97% polyethylene and also a thermoplastic polymer.

The raw material production mostly depends on the cost and availability of crude oil. Polyethylene density can be classified into three major groups based on their possible crystalline structure percent, namely;

Low-Density Polyethylene raw material (LDPE)

Medium Density Polyethylene raw material (MDPE) and

High-Density Polyethylene raw material (HDPE).

Based on other classes of raw materials including their field of long life and high performance; high strength of the economy of most preferred percentage levels (97%) of the product are used crude and also applicable for production of raw materials of polyethylene.

Some properties thermoplastic polyethylene are:

1. HDPE is a good thermal insulation

2. HDPE Pipes are non-toxic material

3. HDPE Pipe is very resistant to different weather conditions

4. HDPE Pipes have lower level compared to metal pipe friction losses

5. HDPE Pipes reduces flow noise

6. HDPE Pipe despite high resistance to stress cracking

7. HDPE Polyethylene Pipe has -30 and -60 degree to strength

8. HDPE Pipe is very suitable for radioactive waste

9. HDPE Pipe has a high resistance to pressure and tearing

10. High-Density Polyethylene Pipe is resistance to corrosion

11. HDPE Pipe is easy and reliable to assemble

Advantages of HDPE Pipes

HDPE pipes have a very long history of about 60years in technological developments and have positively influenced until today with the most preferred tube. Some of these advantages are:

(1) HDPE pipes are environmentally friendly

(2) HDPE pipes maintain the usual properties of the fluid inside them.

(3) HDPE pipes have a high resistance to chemicals.

(4) HDPE pipes are not affected by the underground.

(5) HDPE pipes can be used in many areas where a lot of seismic activity is very comfortable because of its high elastic properties. It can also orient itself according to the direction of movement of ground motion and does not break easily.

(6) HDPE pipes have inner surfaces that are suitable in drinking water systems

(7) HDPE pipe is highly resistant to acids and alkalis. Only damaged by nitric acid.

(8) HDPE pipes welding and assembling are very simple.

Conclusion

The HDPE pipe is one of the most generally used pipe which is easy to handle, with efficient performance, easy to couple and economical and they are produced using the HDPE pipe extrusion line.

However, for the best deal and product, contacting an experienced HDPE pipe extrusion line supplier is the best way to have the best HDPE pipe extrusion line price as well as HDPE products.